News

Archive for the ‘Mixers’ Category

Viscosity of Xanthan Gum at Various Concentrations Video

VIEW VIDEOS

Viscosity of Xanthan Gum at various concentrations – The first video shows the viscosity and flow characteristics of correctly hydrated Xanthan gum solutions at a range of viscosities up to 6%. All samples were dispersed and hydrated using a Silverson High Shear mixer. A food grade Xanthan gum was used but it should be noted that results can vary widely according to the brand and grade of gum used. The mixing system will also have an effect on the final viscosity obtained as incorrect dispersion and hydration can cause agglomerates in the mix which will reduce the yield of thickening effect. The example here illustrates the viscosity and flow characteristics that can be expected with maximised yield when a solution is prepared using a Silverson mixer.

The Silverson Viscosity Comparison Guide – The 2nd video is a simple guide to the different viscosity (thickness) of everyday products. This guide is useful for gauging the viscosity of the product you are mixing, all products shown in this video can be processed using a Silverson mixer.

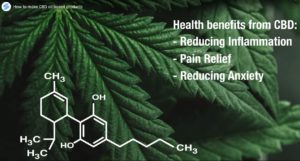

High Shear Mixing for CBD Oil Based Products

The incorporation of CBD into foods – as well as cosmetics and pharmaceuticals – is becoming one of the fastest growing trends in the process industry. Cannabidiol, also known as CBD is an oil derived from cannabis. It contains none of the psychoactive ingredient tetrahydrocannabinol (THC), so there is no ‘high’ from it. A variety of different products such as beverages, gummies, snacks and baked foods containing CBD oil are now available. Silverson mixers are increasingly being used for R&D and small scale production in this emerging market.

The incorporation of CBD into foods – as well as cosmetics and pharmaceuticals – is becoming one of the fastest growing trends in the process industry. Cannabidiol, also known as CBD is an oil derived from cannabis. It contains none of the psychoactive ingredient tetrahydrocannabinol (THC), so there is no ‘high’ from it. A variety of different products such as beverages, gummies, snacks and baked foods containing CBD oil are now available. Silverson mixers are increasingly being used for R&D and small scale production in this emerging market.

If you’d like to learn more, please view video in the Silverson Gallery

MAG MIXERS FOR FOOD AND BEVERAGE PROCESSING

As seen in Processing Magazine By Frank Sequino June 10, 2019

Taking a cue from the pharmaceutical industry, food and beverage processors can use these proven components to achieve better process isolation and containment.

Recalls and cross-contamination issues continue to plague food and beverage producers. Quite often, the problem can be traced back to a process step that is done in an open vessel. The pharmaceutical industry has addressed this by using closed vessels with magnetically driven agitators known as mag mixers, but the continued growth of the use of mag mixers is not limited to applications in the pharmaceutical market. There are also significant advantages in the food and beverage markets.

Mag mixers have been a staple in pharmaceutical processes since their inception, but there has always been an imaginary dividing line between the sanitary requirements in the pharmaceutical industry and those of other sanitary industries. For example, “clean” in the food and beverage industry isn’t the same as “clean” in the pharmaceutical industry. That line is becoming blurrier every day. Today, terms like ultraclean, ultrasanitary and hygienic are commonly used, but their interpretation seems to vary from one person to the next. Regardless of one’s interpretation, it is easy to see that the food and beverage industry is heading in the direction of the pharmaceutical industry in terms of sanitary practices. As product recalls grow more prevalent, the need for the industry to have isolation and containment during processing has never been more prominent.

Figure 1. Anatomy of a mag mixer

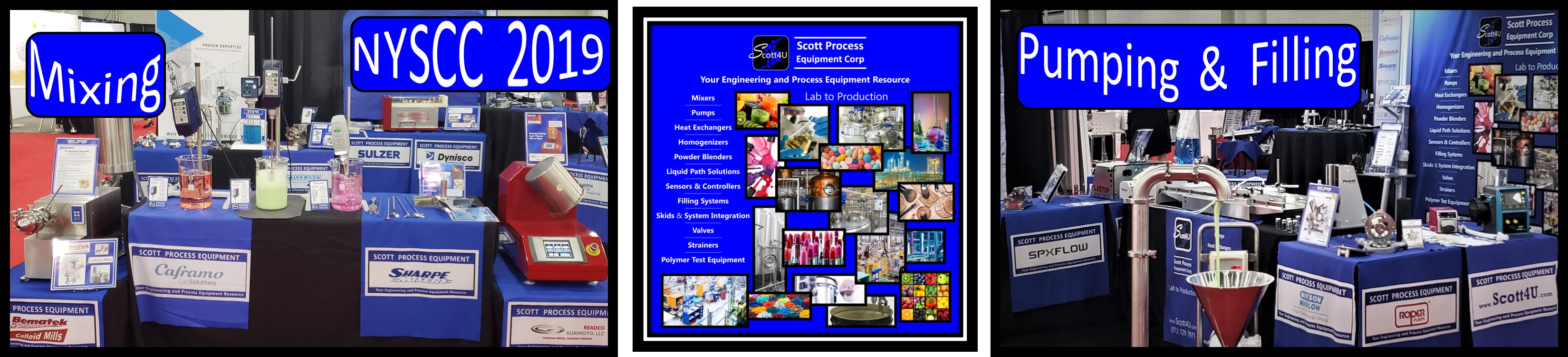

NYSCC Suppliers’ Day 2019

For all your Mixing, Pumping and Filling Needs!

We enjoyed meeting and speaking with so many customers at the Scott Process Equipment Booth at the 2019 NYSCC Suppliers’ Day.

Committed to our customers, the Scott4U sales team is focused on finding the right process equipment or an integrated system for each unique application.

Engineering and Process Equipment Resource

Lab to Production

Representing Premier Manufacturers

NYSCC 2019 Suppliers’ Day

5/7-5/8 — Scott4U Booth 1667

See the equipment first-hand at the Scott4U Booth #1667 and schedule an onsite appointment and demo.

Products that will be Featured at the Scott4U Booth include the Watson-Marlow’s CERTA pump, Caframo Stirrers (BDC3030, BDC1850 & BDC2010), Silverson L5MA Mixer, Readco Powder Blender, Bematek’s Colloid Mill, and more.

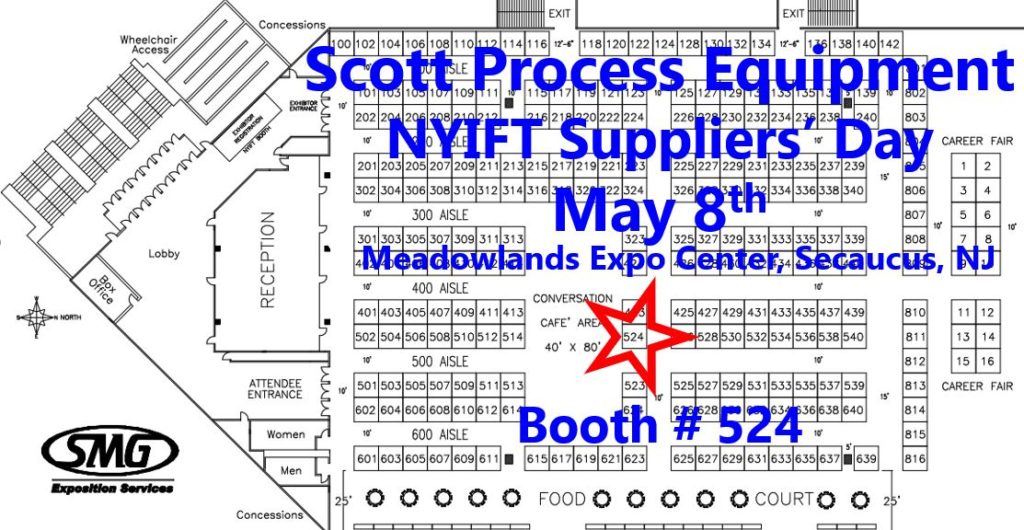

(more…)NYIFT 2019 – Visit Scott4U at Booth 524

New York Institute of Food Technologists

2019 Suppliers Day & Mini Career Fair

Wednesday March 20, 2019 3:30 – 6:00 p.m.

Stop by the SCOTT PROCESS Booth #524

Meadowlands Expo Center | 355 Plaza Drive, Secaucus, NJ 07094

Bematek Colloid Mill featured at NYSCC

The Bematek Colloid Mill Leads Technology Innovation in Homogenizing, Emulsifying, and Dispersing for Cosmetic Formulations

View Bematek’s Colloid Mill Live!

Bematek’s Colloid Mill Will be featured in the Scott Process Equipment Corp Booth #1581 at the 2018 New York Society of Cosmetic Chemists (NYSCC) Suppliers’ Day on May 15th and 16th at the Javits Convention Center in New York City.

Valued as an industry innovator, Bematek brings more than 70 years experience to high-shear colloid mill design. We are inspiring process industry innovation and delivering solutions to meet the increasingly complex manufacturing demands of the cosmetic chemist.

The wet milling of formulations is one of the oldest processing activities that still exists today in modern manufacturing environments. The reduction of particles in dispersions and droplets in emulsions is done by applying hydraulic and mechanical shear to various process ingredients. Bematek colloid mills are recognized as the equipment of choice for increasing the stability of dispersions and emulsions in today’s complex homogenizing processes.

The Bematek Colloid Mill is a conical rotor/stator mill for processing colloidal dispersions, emulsions and suspensions, and works on the principals of shear rate residence time.

- Rotor Speed

- Rotor/Stator Gap

- Rotor/Stator Surface Profiles

- Flow Rate

These parameters make scale-up from R&D to full production simple and reliable.

NYIFT Suppliers’ Day 2018

NYSCC Suppliers’ Day 2018

Scott Process Equipment announces they will be exhibiting at the 2018 New York Society of Cosmetic Chemists (NYSCC) Suppliers’ Day on May 15th and 16th 2018 at the Javits Convention Center, NYC

Scott Process Equipment announces they will be exhibiting at the 2018 New York Society of Cosmetic Chemists (NYSCC) Suppliers’ Day on May 15th and 16th 2018 at the Javits Convention Center, NYC

Save the Date — May 15th and 16th 2018

Stop by Booth # 1581

Since 1989, Scott Process Equipment has been the Engineering and Process Equipment Resource for the personal-care and cosmetics industry. Engineers first, with decades of experience, the sales team are honest, straight-forward and service-oriented professionals, representing premier pumps, mixers, homogenizers, powder blenders, sensors, controllers, scales, valves, filling systems, strainers, and heat transfer equipment manufacturers. Scott4U is focused on finding the right process equipment or an integrated system for your unique application. Robust Line Card includes Bematek, Doyle & Roth, Dynisco. Hardy Process Solutions, Northern Pumps, Pick Heater, Readco, Roper Pumps, Sharpe Mixers, Silverson Machines, SPXFlow, Steridose, Sulzer Chemtech, Unibloc Pump, Watson-Marlow Fluid Technology Group, (Watson-Marlow Pumps, Watson-Marlow Tubing, Flexicon Liquid Filling, Bredel Hose Pumps, Masosin Process Pumps, Bio-Pure, ASEPCO, Flow Smart, and AFLEX Hose) and Zenith Pumps. Scott Process Equipment serves northern New Jersey, the lower counties of New York and Connecticut, NYC and Long Island. Choose Scott4U for all your Personal Care & Cosmetics Industry Engineering and Process Equipment Needs.

For more information about the NYSCC view the Scott Process Profile at https://nysuppliers18.mapyourshow.com/7_0/exhibitor/exhibitor-details.cfm?ExhID=2196

Steridose Exhibiting at Interphex 2018

Stop by the Steridose Booth #3921 at Interphex Show, April 17-19, 2018 at the Javits Center, NYC

INTERPHEX is the premier pharmaceutical, biotechnology, and medical device development and manufacturing event where you can “Experience Science through Commercialization”.

Steriose specializes in the design and manufacturing of aseptic process equipment. Sterimixer is a mag drive mixer that eliminates risk of contamination, assures efficient and low mixing, with high CIP/SIP performance. With capacities from 5 to 40,000 liters, it is available as low and medium shear. Sterivalve, radial diaphragm valve features a zero dead leg design, with sizes ranging from 1/2″ to 3″.

Steriose specializes in the design and manufacturing of aseptic process equipment. Sterimixer is a mag drive mixer that eliminates risk of contamination, assures efficient and low mixing, with high CIP/SIP performance. With capacities from 5 to 40,000 liters, it is available as low and medium shear. Sterivalve, radial diaphragm valve features a zero dead leg design, with sizes ranging from 1/2″ to 3″.