News

See the Watson-Marlow Certa Pump in action at the Scott4U NYSCC Suppliers’ Day Booth

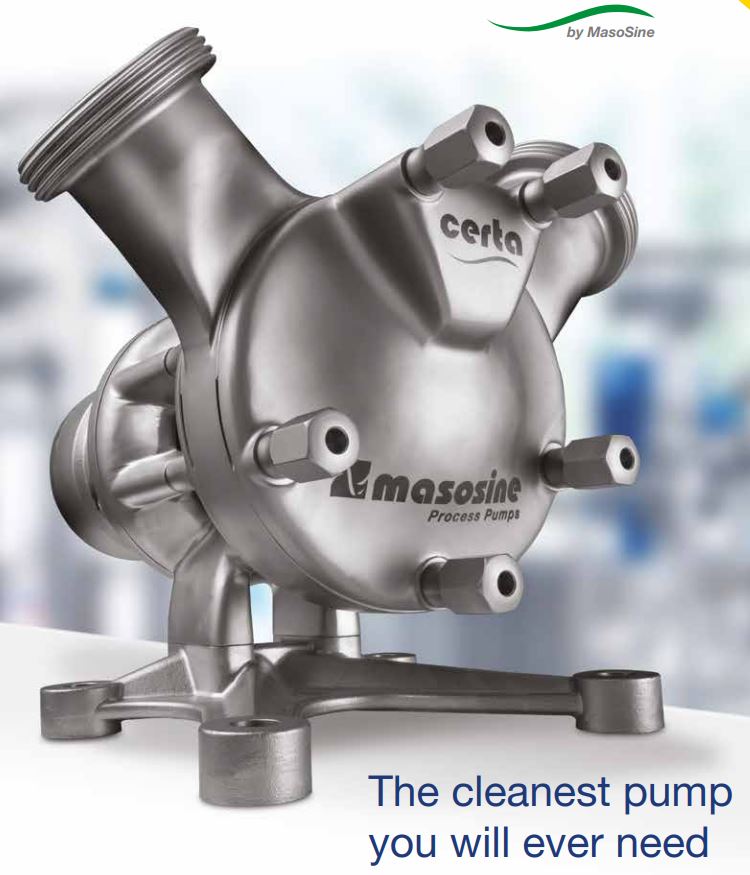

The MasoSine Certa pump is a highly reliable and economical Positive Displacement Pump for low sheer, no pulsation, high viscosity applications ideal for food & beverage, and cosmetics & personal care industries. The exclusive sinusoidal rotor overcomes the limitations of conventional rotary lobe pumps to produce powerful suction with low shear, low pulsation, and gentle handling…all with simple and fast maintenance and 3-A certification.

MasoSine engineers have overcome the limitations of conventional rotary lobe pumps to create one of the most efficient and reliable positive displacement pumps available.

MasoSine’s exclusive single shaft and single sinusoidal rotor are the centerpieces of an innovative, simple design. With a single shaft and rotor, there is no need for the complex timing gears and multiple seals associated with conventional rotary lobe pumps. One rotor, one shaft and one seal equate to simple and economic maintenance.

Highly reliable MasoSine positive displacement pumps are the result of over 25 years of engineering innovation and product development. Customers benefit from less waste and faster processing with low shear, high suction, low pulsation, gentle handling of whole foods or highly viscous products, and simple economical cleaning and maintenance.

Maintenance takes minutes and can be performed in-place by a line operative. Replace off-the-shelf wear components to restore to “new pump” performance.

- A single sinusoidal rotor creates four evenly sized chambers as it rotates

- Fluid is “pulled” through the inlet into each chamber in turn

- The chamber rotates, contracts, closes then discharges fluid through the outlet port

- The opposite chamber opens to draw in more fluid, resulting in a smooth flow with virtually no pulsation

- A gate functions as a seal between the inlet and outlet of the pump, preventing fluid escaping

- Simple maintenance performed in place by a line operative

- Bi-directional running enables duty fluid to be returned to source

- Separation between the wet end and dry end ensures no contamination