News

Author Archive

High Shear Mixing for CBD Oil Based Products

The incorporation of CBD into foods – as well as cosmetics and pharmaceuticals – is becoming one of the fastest growing trends in the process industry. Cannabidiol, also known as CBD is an oil derived from cannabis. It contains none of the psychoactive ingredient tetrahydrocannabinol (THC), so there is no ‘high’ from it. A variety of different products such as beverages, gummies, snacks and baked foods containing CBD oil are now available. Silverson mixers are increasingly being used for R&D and small scale production in this emerging market.

The incorporation of CBD into foods – as well as cosmetics and pharmaceuticals – is becoming one of the fastest growing trends in the process industry. Cannabidiol, also known as CBD is an oil derived from cannabis. It contains none of the psychoactive ingredient tetrahydrocannabinol (THC), so there is no ‘high’ from it. A variety of different products such as beverages, gummies, snacks and baked foods containing CBD oil are now available. Silverson mixers are increasingly being used for R&D and small scale production in this emerging market.

If you’d like to learn more, please view video in the Silverson Gallery

MAG MIXERS FOR FOOD AND BEVERAGE PROCESSING

As seen in Processing Magazine By Frank Sequino June 10, 2019

Taking a cue from the pharmaceutical industry, food and beverage processors can use these proven components to achieve better process isolation and containment.

Recalls and cross-contamination issues continue to plague food and beverage producers. Quite often, the problem can be traced back to a process step that is done in an open vessel. The pharmaceutical industry has addressed this by using closed vessels with magnetically driven agitators known as mag mixers, but the continued growth of the use of mag mixers is not limited to applications in the pharmaceutical market. There are also significant advantages in the food and beverage markets.

Mag mixers have been a staple in pharmaceutical processes since their inception, but there has always been an imaginary dividing line between the sanitary requirements in the pharmaceutical industry and those of other sanitary industries. For example, “clean” in the food and beverage industry isn’t the same as “clean” in the pharmaceutical industry. That line is becoming blurrier every day. Today, terms like ultraclean, ultrasanitary and hygienic are commonly used, but their interpretation seems to vary from one person to the next. Regardless of one’s interpretation, it is easy to see that the food and beverage industry is heading in the direction of the pharmaceutical industry in terms of sanitary practices. As product recalls grow more prevalent, the need for the industry to have isolation and containment during processing has never been more prominent.

Figure 1. Anatomy of a mag mixer

Measuring Die Swell Using a Capillary Rheometer

Azadeh Farahanchi, Rheological Scientist, Ph.D

Dynisco Polymer Evaluation Blog

Die swell has been used as a qualitative measure of polymer melt elasticity for quality control purposes in plastics industry. Die swell also can be used for analysis of extrudate smoothness in an extrusion process.

Die swell is expansion of extrudate after exiting the die. It happens as a result of the molecular orientation that is generated by the flow in the die (with the greatest extension occurring near the wall) and recoiling after exiting the die (contracting in the flow direction and expanding in directions perpendicular to the flow). In other words, this phenomenon is produced by plastic materials memory. As the extrudate exits the die, it tries to return to its initial molecular coil shape.

.jpg)

Dynisco LCR capillary rheometer is able to measure the diameter of the extrudates using a CCD element detection and laser beam. This accessory element has the following specification: light source of 800 nm laser, resolution of 2.75 µm, measuring range of 0.13-23 mm, response time of 1.4 ms, and accuracy of +/- 0.003 mm.

.jpg)

NYSCC Suppliers’ Day 2019

For all your Mixing, Pumping and Filling Needs!

We enjoyed meeting and speaking with so many customers at the Scott Process Equipment Booth at the 2019 NYSCC Suppliers’ Day.

Committed to our customers, the Scott4U sales team is focused on finding the right process equipment or an integrated system for each unique application.

Engineering and Process Equipment Resource

Lab to Production

Representing Premier Manufacturers

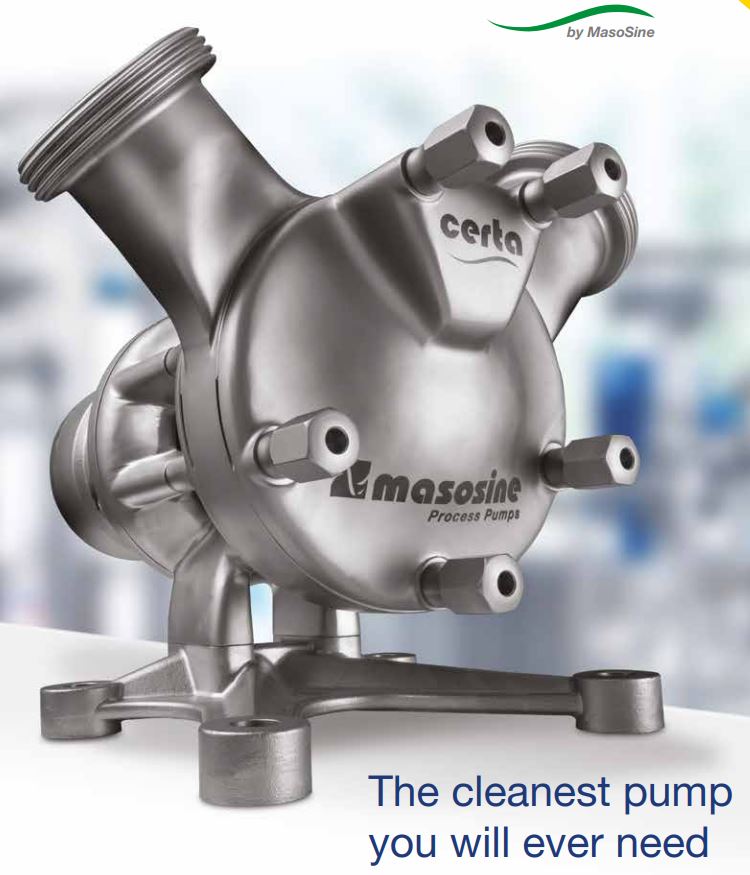

See the Watson-Marlow Certa Pump in action at the Scott4U NYSCC Suppliers’ Day Booth

The MasoSine Certa pump is a highly reliable and economical Positive Displacement Pump for low sheer, no pulsation, high viscosity applications ideal for food & beverage, and cosmetics & personal care industries. The exclusive sinusoidal rotor overcomes the limitations of conventional rotary lobe pumps to produce powerful suction with low shear, low pulsation, and gentle handling…all with simple and fast maintenance and 3-A certification.

MasoSine engineers have overcome the limitations of conventional rotary lobe pumps to create one of the most efficient and reliable positive displacement pumps available.

NYSCC 2019 Suppliers’ Day

5/7-5/8 — Scott4U Booth 1667

See the equipment first-hand at the Scott4U Booth #1667 and schedule an onsite appointment and demo.

Products that will be Featured at the Scott4U Booth include the Watson-Marlow’s CERTA pump, Caframo Stirrers (BDC3030, BDC1850 & BDC2010), Silverson L5MA Mixer, Readco Powder Blender, Bematek’s Colloid Mill, and more.

(more…)INTERPHEX stop by to see Scott Process at Watson-Marlow Booth 2833

Interphex 2019 | Visit Booth 2833 | April 2-4, 2019 | Javits Center, NYC

Scott Process Engineers and WMFTG experts will be on hand to demonstrate the industry leading Quantum peristaltic pump with patented ReNu single-use (SU) cartridge technology.

See first-hand Flexicon’s FPC60; Flexible, Configurable Fill/Finish System.

Rheological Data can Help to have a Better Metal Injection Molding Process

Azadeh Farahanchi, Rheological Scientist, Ph.D

Dynisco Polymer Evaluation Blog

How Rheological Data from a Capillary Rheometer Can Help to Have a Better Metal Injection Molding (MIM) Process?

Metal injection molding (MIM) is an advanced metalworking process to produce parts with complex shapes and high tolerances from a mixture of polymeric binder and metal particles/powders at specific volume ratios (feedstock). The flexibility and mass production of injection molding process makes it to be a great replacement to the traditional metallurgy process and therefore, MIM has been growingly performed in industry for large-number production of metal parts.

.jpg)

One of the key factors in any MIM process is the flow behavior of the feedstock during filling of of the mold. In order to have a defect free molding process (without jetting, short shot, sink mark, crack, etc.) with desired mechanical strength (tensile, flexural, failure stress, etc.) in the final products, understanding of the rheological properties of the binder and feedstock is necessary. The rheological analysis also helps to have defect free debinding and sintering procedures which are the final steps in a MIM process and gives the required mechanical strength to the final products.

In terms of rheological properties, there are three main factors which have significant effect on a MIM process namely, viscosity at the processing shear rate, thermal sensitivity, and shear thinning behavior of the feedstock. All these factors can be analyzed using a capillary rheometer. Since this rheological characterization method provide a wide range of shear rate, it is the best approach to study feedstock melt behavior in an injection molding process.

INTERPHEX 2019 – WMFTG Booth #2833

Interphex 2019 | Visit Booth 2833 | April 2-4, 2019 | Javits Center, NYC

Choose Scott Process and Watson-Marlow

for all your Bio-Pharm & Pharmaceutical Needs

Quantum redefines peristaltic pump performance for single-use downstream bioprocessing.

Scott Process Engineers and WMFTG experts will be on hand to demonstrate the industry leading Quantum peristaltic pump with patented ReNu single-use (SU) cartridge technology.

![]()

Easy Streamlined Batch Production with Flexicon’s New FPC60

Uniquely flexible, configurable fill/finish system.

- Highly accurate peristaltic filling

- Fast and flexible change over between batches and vial sizes

- Zero product waste in batch start up

- Designed for ready-to-use vials and single-use fluid paths

See first-hand, the Flexible, Configurable Fill/Finish System at Interphex

![]()

See how we can help take production to a

new level with the Flexicon FPC60.

Uniquely flexible, configurable fill/finish system

Interphex 2019 | Visit Booth 2833 | April 2-4, 2019 | Javits Center, NYC

Biotechnology and pharmaceutical fluid-in-motion expert Watson-Marlow Fluid Technology Group (WMFTG), will be showcasing its unparalleled bioprocessing products including the New Flexicon FPC60, highly accurate peristaltic fill/finish system offers customers exceptional production flexibility. A wide variety of modules are available for the system, allowing users to create their own unique filling solution to suit small-batch applications. The modules include vial infeed, filling, stoppering, capping, auto-reject, gas purging and product outfeed. As a result, the FPC60 is ideal for bioprocessing applications.