Watson-Marlow Fluid Technology Group (WMFTG) is the world leader in niche peristaltic pumps and associated fluid path technologies for the food, pharmaceutical, chemical and environmental industries.

Watson Marlow works closely with their customers to demonstrate how WMFTG positive displacement pumps ensure accurate metering, transfer and filling, and can deliver significant process efficiencies over the lifetime of the equipment.

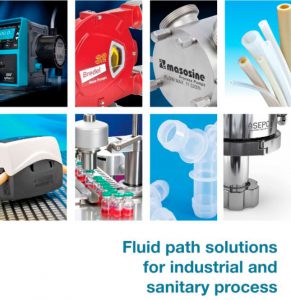

Their established brands, each with their own area of expertise, together offer customers unrivalled solutions for their pumping and fluid transfer applications.

Their established brands, each with their own area of expertise, together offer customers unrivalled solutions for their pumping and fluid transfer applications.

- Watson-Marlow Pumps

- Watson-Marlow Tubing

- Flexicon Liquid Filling

- Bredel Hose Pumps

- MasoSine Process Pumps

- BioPure

- ASEPCO

- Flow Smart

Customers demand many things from their process equipment and the prime concern is maintaining product integrity. Positive displacement pump companies need to supply products which meet a range of requirements including:

- Low cost of ownership

- Reliability

- Ease of maintenance

- Proven after sales service

- ROI

Watson-Marlow pumps bring you:

- Accurate and repeatable flow rates

- Contamination free pumping – ideal for shear-sensitive fluids, viscous sludges or slurries, and aggressive acids and caustics

- Easy to install, operate and maintain

- Virtually maintenance free – no expensive seals, valves, diaphragms or rotors to leak, clog or corrode

Watson Marlow Industries

Watson-Marlow Fluid Technology Group and WMFTG Brands Resource Library

BRANDS

Watson-Marlow Pumps: peristaltic tube pumps including the new Qdos pumps which negate the need for ancillaries, boost productivity and cut chemical waste, via more accurate, linear and repeatable metering than conventional solenoid or stepper-driven diaphragm metering pumps in the environmental and mining sectors.

Watson-Marlow Pumps: peristaltic tube pumps including the new Qdos pumps which negate the need for ancillaries, boost productivity and cut chemical waste, via more accurate, linear and repeatable metering than conventional solenoid or stepper-driven diaphragm metering pumps in the environmental and mining sectors.

Watson-Marlow Tubing: precision tubing including Pumpsil platinum-cured silicone, plays a key role in biotechnology and pharmaceutical manufacturing processes. Tubing manufactured in a ISO 14644-1 Class 7 clean room, provides absolute sterility throughout the fluid handling process.

Watson-Marlow Tubing: precision tubing including Pumpsil platinum-cured silicone, plays a key role in biotechnology and pharmaceutical manufacturing processes. Tubing manufactured in a ISO 14644-1 Class 7 clean room, provides absolute sterility throughout the fluid handling process.

![]() Flexicon Liquid Filling: aseptic filling and capping systems ease customer validation in demanding contamination-free pharmaceutical and clinical diagnostic applications. Designed for small to medium sized batch production, systems provide filling accuracy of ±0.5% over volumes from 0.5ml to 250ml.

Flexicon Liquid Filling: aseptic filling and capping systems ease customer validation in demanding contamination-free pharmaceutical and clinical diagnostic applications. Designed for small to medium sized batch production, systems provide filling accuracy of ±0.5% over volumes from 0.5ml to 250ml.

Bredel Hose Pumps: heavy-duty hose pumps which are self-priming, dry running, and with no internal valves. Hose pumps improve processes by eliminating troublesome and costly ancillary items like anti-siphon valves, back-pressure valves, degassing valves or run-dry protection, in high viscosity sludge handling and abrasive fluid duties.

Bredel Hose Pumps: heavy-duty hose pumps which are self-priming, dry running, and with no internal valves. Hose pumps improve processes by eliminating troublesome and costly ancillary items like anti-siphon valves, back-pressure valves, degassing valves or run-dry protection, in high viscosity sludge handling and abrasive fluid duties.

MasoSine Process Pumps: sinusoidal pumps designed for sanitary, food and industrial applications. Pumps produce powerful suction with low shear and low pulsation, to safely transfer delicate products without risk of degradation. The highly efficient MasoSine pumps’ working principle means they can contribute to energy savings and a reduction in CO2.

MasoSine Process Pumps: sinusoidal pumps designed for sanitary, food and industrial applications. Pumps produce powerful suction with low shear and low pulsation, to safely transfer delicate products without risk of degradation. The highly efficient MasoSine pumps’ working principle means they can contribute to energy savings and a reduction in CO2.

BioPure: single-use tubing connector systems for biopharmaceutical customers. There is clear synergy and a significant growth opportunity presented by bringing together BioPure’s product range and WMFTG’s products to meet the needs of the rapidly growing single-use biopharmaceutical market.

BioPure: single-use tubing connector systems for biopharmaceutical customers. There is clear synergy and a significant growth opportunity presented by bringing together BioPure’s product range and WMFTG’s products to meet the needs of the rapidly growing single-use biopharmaceutical market.

ASEPCO: design and manufacture of high purity aseptic valves for the biopharmaceutical industry. Asepco utilizes patented, market-leading technology to improve sterility within the biotechnology production process.

ASEPCO: design and manufacture of high purity aseptic valves for the biopharmaceutical industry. Asepco utilizes patented, market-leading technology to improve sterility within the biotechnology production process.

Flow Smart: a range reinforced platinum silicone hoses and high performance sanitary gasket products

Flow Smart: a range reinforced platinum silicone hoses and high performance sanitary gasket products