Steridose is a Swedish company highly specialized in design, development and manufacturing of Sterimixer®, Mag-Drive mixers for sanitary applications in the bio-pharm, pharmaceutical, personal care product, and food & beverage markets.

Steridose is a Swedish company highly specialized in design, development and manufacturing of Sterimixer®, Mag-Drive mixers for sanitary applications in the bio-pharm, pharmaceutical, personal care product, and food & beverage markets.

Sterimixer® The Original Magnetic Coupled Mixer for Pharmaceuticals

- The Sterimixer may be the most widely used magnetically coupled mixer for bio-pharmaceutical applications world-wide. It consists of the following major components: impeller, bearing, weld-plate, drive unit and control box. All wetted parts of the impeller and the weld-plate are made of AISI 316 L (EN 1.4404). Interchangeable impeller designs are available.

Magnetic coupled mixer for Food and Cosmetics

- The new range of Sanimixer® is available in sizes up to 30 000 L (7 926 usgal) general mixing or 40 000 L (10 568 usgal) gentle mixing (ref. water). The bottom mounted mixer with open type impeller is a cost-effective alternative to top mounted mixers and the natural choice for food, beverage, dairy, and cosmetic applications with high demands regarding cleanability and sterility.

The different types of Sterimixer designs can be found in upstream, downstream and fill & finish applications:

- Storage: the liquid is kept in constant movement in order to keep two or more different liquids mixed in a constant concentration and temperature throughout the vessel. A typical low-shear (see box) biopharmaceutical application in storage tanks, buffer and media hold, etc.

- Heat transfer: the liquid needs to be in constant movement in order to achieve a constant temperature in heated (jacketed) vessels.

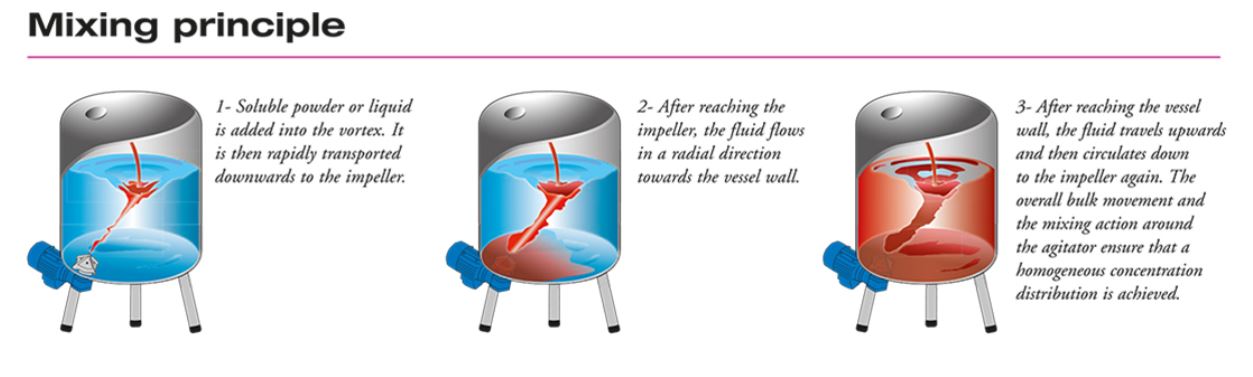

- Mixing miscible liquids: the pumping action of the mixer mixes the liquids with the final purpose of having a homogeneous composition in the entire tank. Higher pumping rates will speed up mixing but might cause more shear and undesirable vortex forming. A balance between mixing time and allowable shear and vortex is sought.

- Dissolving solids in liquid: similar to mixing miscible liquids, the pumping action helps dissolving and keeping the ingredients in solution. Solids that are hard to incorporate often require a higher degree of shear and the ability to form a vortex.

- Suspensions: solids are kept in suspension in a liquid phase. Low shear mixers are typically used. The amount of transferred power required depends on the particle settling speed and the degree of suspension that is desired (e.g. o

ff bottom or uniform suspension).

ff bottom or uniform suspension).

Dissolving gas in liquid: this is common in bioreactors where air is introduced, and the mixer helps dispersing the bubbles in order to increase oxygen transfer. The degree of shear is related to the oxygen transfer rates required by the application.